-

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Input | 1-phase 220V / 3-phase 380V | Output | 5/10/40/80/120KW |

|---|---|---|---|

| Frequency | 2.5~60KHz | Electric Design | Digital Control |

| Resonance | Series Resonance | Control Mode | Temperature Control |

| Control Precision | High Precision | Heating Temp. | 788℃ |

| Highlight | 160kw induction heater machine,Anti Corrosion Coating induction heater machine,Pipe Preheating induction heating system |

||

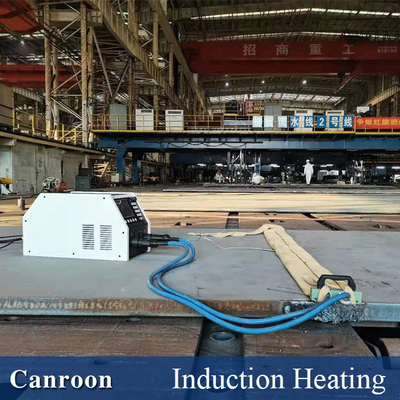

High quality factory price 160kw induction heater pipe preheating

machine for field joint anti corrosion coating

Welding preheating and post-heating is an important application field of induction heating. The welding of steel

after preheating can reduce the stress,improve the welding strength,and prevent cracking.Post-heating is used

for dehydrogenation,annealing,tempering,normalizing and other processes.

Induction heating is used for welding preheating and post-heating.It has the characteristics of good controllability,

can realize complex process program,non-contact heating,wide adaptability,high efficiency,and energy density,

and can realize on-line heating.

CR2000 is widely used and welcomed by oil&gas piping, and power plant construction & repair.

Application of shink fitting for motor stator is also very efficient.

Induction Heating Power Source:

CR2000 induction heating generatore covers power 5KVA/10KVA/40KVA/80KVA/120KVA.

All designed with perfect portability and compact in size.

![]()

CR2000 series medium frequency induction heating system is designed and manufactured by Canroon,

specially for using of welding preheat, post weld heat treatment (DHT dehydrogenation heat treatment,

ISR intermediate stress relief), and joint anti-corrosion coating.

Specifications:

| Type | Input | Output | Inductance range | Dimension | Weight | IP |

| CR2000-005B-12SF |

Power: 5KVA |

Power: 4.2kW |

1~160uH |

W:242.9MM |

16Kg | IP23 |

| CR2000-005B-14TF |

Power: 5KVA |

Power: 4.5kW |

2.2-300uH | W:263MM H:302MM D:535MM | 18.5Kg | IP23 |

| CR2000-010B-14TF |

Power: 10KVA |

Power: 9W |

IP23 | |||

| CR2000-040B-14TF |

Power: 40KVA |

Power: 35kW |

2.2-300uH | W:544MM H:762MM D:730MM | 115Kg | IP23 |

| CR2000-080B-14TF |

Power: 80KVA |

Power: 72kW |

3.0-500uH | W:592MM H:845MM D:801MM | 190Kg | IP23 |

| CR2000-120B-14TF |

Power: 120KVA |

power: 108kW |

3.0-500uH | W:592MM H:845MM D:801MM | 190Kg | IP23 |

Accessories:

We provide complete system for welding preheat / PWHT / Joing anti-corrosion coating. All necessary

accessories in these process, you can find in Canroon, and all designed and manufactured by Canroon

to ensure its perfect performance with our CR2000 induction heating system.

![]()

Customized Inductor:

Canroon provide customized inductor to adapt various workpieces, and ensure easier operation and higher

working efficiency. According to the workpiece and process requirements to customize a variety of tooling

inductors including: Blanket inductor,C-type inductor,Split-core/Clamp inductor(Hydraulic type,Manual type),

Plate / Flat inductor, Ring inductor ,flexible heating cable and so on.

Applications:

Preheating for circular seam / longitudinal seam welding;

Preheating for joint anti-corrosion coating;

Annealing

PWHT

![]()

![]()

Features:

- Friendly Interface and Accurate Control

The control board offers various parameters for setting so the heating process can be controlled

precisely by giving value to temperature, time, heating rate, cooling rate, etc.

- Various Control Mode

The interface offers two basic control mode to choose including temperature control and power

control. The former one has 4 modes of preheat, bake-out, PWHT, custom. The last one has

2 modes of constant power and power VS time. Each mode offers different parameters to set.

Thus brings the benefit of wide applicability and precise control.

- Fault Record

Fault codes will display and be recorded for reference, and system will respond with protection

action like shutdown once fault occurs such as open-loop output or short out.

- Easy Maintenenace

Due to modular design, the maintance will be easy and low-cost.

- Self Diagnosis

Once fault occurs, CR2000 will act with display of fault code, which was detailed explained in the

manual book.

- High Efficiency

This uniquely energy-efficient process converts up to 90% of the expended energy into useful heat,

and time-to-temperature is faster than conventional processes due to the method of applying heat,

reducing cycle time.

- Uniform Heating

The heat is induced within the part itself by alternating electrical current, thus uniform temperature

throughout the heating zone is realized.

- Replaceable Heating Inductor

Apart from induction blanket (blanket type inductor), there are multiple heating inductors for choice

including induction coil/cable, C-type inductor, plate type inductor, Split-core inductor, O type inductor,

all of which are easily dismountable and reconnected to the power source. So the power source

can be used for heating workpiece of different size and shape.

- Abdudant Accessories

We offer multiple accessaries like thermocouple, thermocouple welding machine, digital temperature-recorder,

remote switchgear, output extension cable, insulation blanket, etc. Complete solution saves your time and

ensures you to start work soon after received our delivery.

![]()

![]()

![]()