-

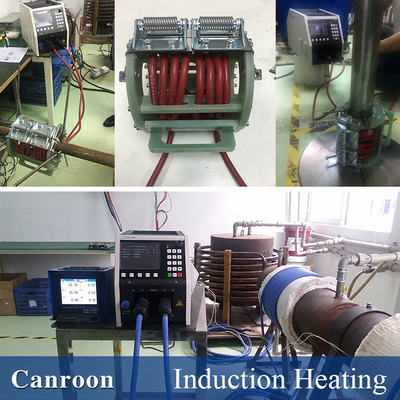

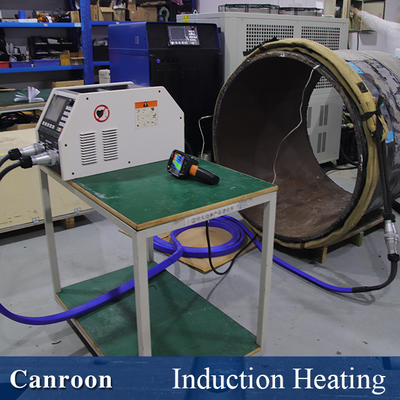

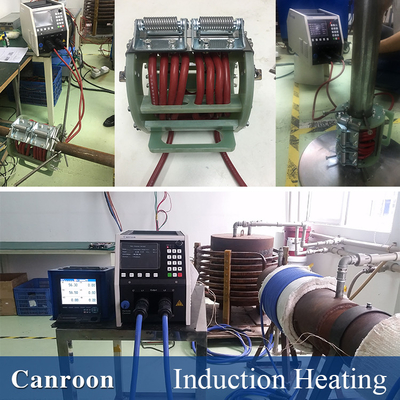

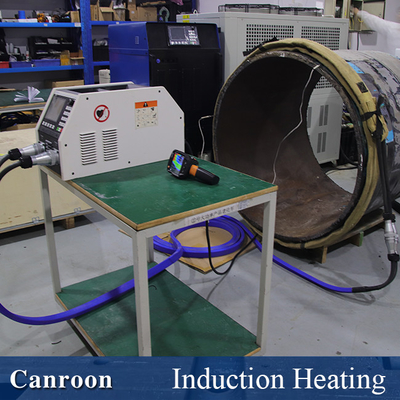

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Input Power | 5KVA | Inductance Range | 1-160uH |

|---|---|---|---|

| Input Frequency | 50-60Hz | Temperature Control | Digital Display |

| Heating Temperature | Can Be High As 788℃ | Input Current | 20.8-22.7A |

| Thermocouple | 6 PCS | Certificate | CE ISO9001 |

| Output Power | 4.5KW(duty Cycle 100%) | Input Voltage | 1-phase 220-240V |

| Highlight | Safe Induction Preheating Welding,Induction Preheating Welding For Gas Pipeline,Induction Preheating Welding For Oil Pipeline |

||

Induction Preheating Welding With Digital Display Temperature Control Input Frequency 50-60Hz

Product Description:

Induction Preheating Welding is a product designed to facilitate oil and gas pipeline construction both Onshore and Offshore. It provides a safe and efficient preheating process that can be used in advance of welding, to ensure that weld joints are effectively heated prior to welding. The product is equipped with a range of features and functions that enable it to reach temperatures as high as 788℃ in a short amount of time. It has an input current of 20.8-22.7A, an input voltage of 1-phase 220-240V, and an output frequency of 5-60KHz. The product model is CR2000-005B-12SF, making it a reliable and efficient solution for preheating welding applications.

Features:

- Product Name: Induction Preheating Welding

- Input Current: 20.8-22.7A

- Input Voltage: 1-phase 220-240V

- Product Model: CR2000-005B-12SF

- Output Power: 4.5KW(duty Cycle 100%)

- Input Frequency: 50-60Hz

- Digital Control: Yes

- Post Weld Heat Treatment: Yes

- Ideal for oil and gas pipeline construction: Yes

Technical Parameters:

| Parameter | Value |

|---|---|

| Product Model | CR2000-005B-12SF |

| Output Frequency | 5-60KHz |

| Heating temperature | Can Be High As 788℃ |

| Input Current | 20.8-22.7A |

| Inductance Range | 1-160uH |

| Temperature Control | Digital Display |

| Material | Carbon Steel/Stainless Steel/Copper/Aluminum |

| Thermocouple | 6 PCS |

| Weight | 22Kg |

| Input Frequency | 50-60Hz |

| Application | Onshore Offshore pipeline, pipe welding preheat, oil and gas pipeline construction |

Applications:

Canroon CR2000 Induction Preheating Welding is widely used in many fields, such as carbon steel, stainless steel, copper and aluminum welding and forming. With digital control and automatic pipe welding machine, it can provide high heating speed and temperature as high as 788℃. This product model CR2000-005B-12SF has an inductance range from 1 to 160uH, input current from 20.8 to 22.7A and input voltage of 1-phase 220-240V. Canroon CR2000 Induction Preheating Welding is a reliable and efficient welding solution.

Customization:

Brand Name: Canroon

Model Number: CR2000

Place of Origin: Shenzhen, China

Input Power: 5KVA

Input Frequency: 50-60Hz

Product Model: CR2000-005B-12SF

Inductance Range: 1-160uH

Material: Carbon Steel/Stainless Steel/Copper/Aluminum

Canroon Induction Preheating Welding is the perfect solution for PWHT and Onshore/Offshore pipeline applications. It is designed with a powerful 5KVA input power and 50-60Hz input frequency, the CR2000-005B-12SF model offers a wide inductance range of 1-160uH and is compatible with Carbon Steel, Stainless Steel, Copper and Aluminum materials.

Packing and Shipping:

Packaging and Shipping of Induction Preheating Welding:

The induction preheating welding should be securely packaged and shipped in compliance with the applicable national regulations and international standards. It is important to ensure that the product is not damaged during transportation. The packaging materials should include shock-proof materials, a waterproof cover, and other materials to protect the product from vibration, shock, and pressure.

The induction preheating welding should be shipped in an appropriate container, such as a wooden box, cardboard box, plastic box, etc., and it should be properly labeled with information about the contents and destination. In addition, the container should be clearly labeled with the name of the shipper and the receiver, and the size and weight of the package should be specified.