-

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Place of Origin | Shenzhen, China |

|---|---|

| Brand Name | Canroon |

| Certification | CE, ISO9001:2008, etc |

| Model Number | CR2100 |

| Minimum Order Quantity | 1 set |

| Price | Negotiable price |

| Packaging Details | wooden case |

| Delivery Time | within 7 days if available in stock |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 500 sets per month |

| Name | IGBT Induction Heater Digital Induction Brazing Machine | Application | Metal Heating, Brazing, Etc |

|---|---|---|---|

| Input Power | 380V , 3-Phase | Certification | CE , ISO9001:2008 |

| Power | 10-60kw | Weight | About 20kg |

| Cooling | Water Cooling | Core Components | PLC, Bearing, Gear |

| Highlight | IGBT Mini Induction Heater,Copper Pipe Mini Induction Heater,Digital Induction Brazing Machine |

||

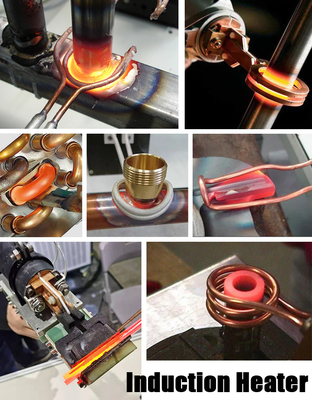

IGBT induction heater digital induction brazing machine for copper pipe welding

Canroon's IGBT Induction heater digital is used extensively in the metalworking industry to heat metals

for hardening, soldering, brazing, and tempering and annealing. The induction-heating process is also

employed in the fusion of metals and the production of high-quality alloys.

Ours portable induction heating generators are built for induction brazing and feature output power of 5-60kw.

Its functions of fast temperature control,energy control and fast beat operation are especially suitable for brazing.

Workpieces:

<> Electric motor: short circuit ring, flip ring, armature winding, flat copper wire, etc.

<> Heat exchanger: copper tube;

<> Automobile die;

<> Crank shaft;

<> Oil&gas pipe.

Product features of IGBT induction heater digital induction brazing machine

for copper pipe welding :

| Brand | Canroon (manufacturer) |

| Model | CR2100- |

| Tech | digital control | module design | induction heating |

| Control Mode | power control mode | temperature control mode |

| Cooling | water cooling |

| Design | IGBT, modular design |

| Heating Material |

all metal: iron, steel, copper, brass, zinc, aluminum, silver, gold, etc |

| Applications | metal heating, brazing, etc |

Advantages of Canroon CR2100 series product:

1. various model for choice

Split type is provided to work with your current chiller.

All-in-one type is designed with built-in chiller, no need for external cooler, less space;

2. high temp | fast heating

Able to reach above 1000℃ within seconds, save our precious time, improve your work efficiency;

3. easy operation

CR2100 can be easily start/stop manually, and scan on workpieces surface to do local heatng.

It can also be integrated into robot arm to serve automatic line.

4. HHT

Compact design, easy to handle for manual work, easy to be integrated into robot arm for automatic work.

Technical Parameters of IGBT induction heater digital induction brazing machine

for copper pipe welding:

| Model | Rated input voltage & frequency | Rated input power | Rated input current | Output frequency | Cooling water pressure / flow rate | Dimension |

| CR2100-010B |

3-phase |

10KVA | 15A |

10~40KHZ |

4~6 bar ≥12L/min

|

L : 591 W : 282 H : 339

|

| CR2100-015B | 15KVA | 22A | ||||

| CR2100-020B | 20KVA | 30A | ||||

| CR2100-025B | 25KVA | 37A | ||||

| CR2100-030B | 30KVA | 45A | ||||

| CR2100-035B | 35KVA | 53A | ||||

| CR2100-040B | 40KVA | 60A | ||||

| CR2100-050B | 50KVA | 75A |

4~6 bar, ≥25L / min |

L : 621.4 W : 282.4 H : 349.4 |

||

| CR2100-060B | 60KVA | 87A |

Brief introduction of IGBT induction heater digital induction brazing machine for copper

pipe welding:

Canroon is China leading manufacturer of induction heating machine, CR2100 series is our widely popular both in China

and oversea countries, digital control, modular design, LED display panel, HHT, detachable inductor, soft induction cable,

water cooling system, see the following picture:

![]()

Handheld coaxial transformer and customized inductor:

HHT (hand held transformer) is easy to operate, and can be integrated with Robot Arm for automotion

production, two buttons to control the machine working:

![]()

All of our IGBT induction heating brazing machine with HHT is carefully packed in wooden case for safe

delivery, by sea, by air according to your need.

Applications of IGBT induction heating brazing machine with HHT :

Induction brazing of short circuit ring, copper wires on motor stator, rotor bar,rotor coil,heat exchanger.

![]()

Application details of IGBT induction heater digital induction brazing machine for copper

pipe welding:

Our induction coil machine can be used for metal brazing, also efficient for hardening, annealing, curing,

paint removal,and other applications that require for metal heat treatment. With fast and uniform heating,

and good performance,induction heating is more and more popular in metal heat treatment. As for our

CR2100 series portable type,we can provide 10-60kw, and inductor can be customized according to your

workpiece for best performance.

Our IGBT Induction heater machines are used for various brazing process such as tube brazing, electrical

rotor brazing, conical drill bit brazing, carbide-edged blade brazing, steel blade brazing and fittings brazing.

![]()

Factory:

![]()

![]()

The exhibitions we attended

![]()

Our certificates

![]()

Packaging Details

Electic induction welding equipment is packed with plastic film, and fixed with rubber belt

Inside the case, covered with foamsOutside covered with customized wooden case.

Our Services

1. keep the quality first and make more products benefit to our customers' need

2.about our Online/Sale service

super and solid quality,Fast and punctual delivery,Standard export package or as customers’ need.

3.After-sale service

Assistance to your project,Repairing and maintenance if any problem occur in the warranty, Installation and

clerks training,Spare and wearing parts for free or with big discount,Any feedback of machines can be told to

us, and we will try our best to support you.

FAQ:

1. Are you a trading company or manufacturer?

We are manufacturer located in Shenzhen, China, specialized in induction heating power for many years.

2. What's the delivery time for sample and bulk order?

Normally we have stock of the mini and medium items, 1-3 days for sample order, 15-40days for 20 GP and 40HQ quantity.

3. I am not so familiar with your machine now. I am not sure i can use it well if i buy it from you.

Dont worry about this any more. With the machine,we will send you a brochure with detail information

with our machine operation. If you need, Video is also available.

4. can you customize the machine for us?

Yes, of course, just tell me your detailed requirement, so I can suggest you most suitable project.

metal heating, brazing, etc