-

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Place of Origin | Shenzhen, China |

|---|---|

| Brand Name | Canroon |

| Certification | CE, ISO9001:2008, etc |

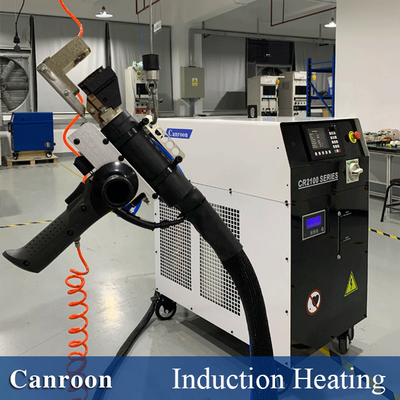

| Model Number | CR2100 |

| Minimum Order Quantity | 1 pcs |

| Price | Negotiation |

| Packaging Details | wooden case |

| Delivery Time | Within 7 days if available in stock |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 500 sets per month |

| Power | 10-50kw | Tech | IGBT Induction Heating |

|---|---|---|---|

| Application | Induction Brazing, Heat Treatment | Cooling Method | Water Cooling |

| Cooling System | Built-in Water Cooling System, | Heating Method | Induction Heating |

| Highlight | Water Cooling Sys Induction Heating Machine,HF Induction Brazing Equipment 3 phase,60HZ HF Induction Heating Machine |

||

IGBT Induction Heating Machine/Induction Brazing Equipment

Power:10-50kw

Applications:metal brazing, annealing, hardening, straightening, curing, paint removal, etc

Frequency:10-40kHZ

Voltage: 3phase, 380-460V, 50/60HZ,

Certificates: ISO, CE, etc

Application industries: aviation, metallurgy, tools and equipment, automotive, etc

Suitable metals: nearly all conductive metals like copper, steel, iron, brass, aluminum, etc

Features: built-in chiller, HHT, universal wheels, digital control, self-fault diagnosis, modular design, etc

IGBT induction heating machine/induction brazing equipment:

Our CR2100 series are especially designed for metal brazing, with water cooling system built-in, it will be

more convenient when real-site working. The main structure concerns: induction heating machine, universal

wheels, watercooling system, soft induction cable, hanger, HHT, detachable inductor.Canroon is China leading

manufacturer of induction heating machine.

Technical parameters of IGBT induction heating machine/induction brazing equipment:

| Model | Rated input voltage & frequency | Rated input power | Rated input current | Output frequency |

| CR2100-010E-14TW1 |

3-phase 400V(±20%) 50/60Hz |

10KVA | 15A | 10~40KHZ |

| CR2100-015E-14TW1 | 15KVA | 22A | ||

| CR2100-020E-14TW1 | 20KVA | 30A | ||

| CR2100-025E-14TW1 | 25KVA | 37A | ||

| CR2100-030E-14TW1 | 30KVA | 45A | ||

| CR2100-035E-14TW1 | 35KVA | 53A | ||

| CR2100-040E-14TW1 | 40KVA | 60A | ||

| CR2100-050E-14TW1 | 50KVA | 75A |

![]()

See the following pictures of the working site:

![]()

![]()

Canroon offer custom service for clients.

Each inductor are designed specially for client’s specific application case, to ensure a perfect matching with

the workpieceand CR2100 power source, and manufactured in high-standard craft to ensure its performance

and robust quality.

Necessary information are required from clients for a professional service provided by Canroon: specific application,

workpiece material and dimensions (better with drawing and pictures).

Inductor is essential to the induction heating process, and many factors contribute to a coil’s effectiveness. It’s

important toinsist on professionally made and maintained coils – preferably from the same people who made you

induction system.

![]()

HHT (hand held transformer)&Inductors

![]()

Two control keys:

Trigger : pull to start heating, loose to stop heating;

Button : lock the trigger (pull the trigger and press the button), heating will be continuous.

Advantages of IGBT induction heating machine/induction brazing equipment:

· Customized Inductor

Canroon provided high-standard customized inductor to CR2100 induction generator, to help you

deal with workpieces of different shap&size.

· High Temp. & Fast Heating

Able to reach >1000℃ within seconds.

· Fault Record

Fault codes will display and be recorded for reference, and system will respond with protection action

like shutdown once fault occurs such as open-loop output or short out.

· Easy Operation

CR2100 can be easily start&stop manually, and scan on workpieces surface to do local heating. It can

also be integrated into robot arm to serve automatic line.

· Accurate Control

The interface offers two basic control modes to choose including temperature control and power control.

Thus brings the benefit of wide applicability and precise control of heating process.

· Easy Maintenance

Due to modular design, the maintenance will be easy and low-cost.

· Self-Diagnosis

Once fault occurs, CR2100 will act with display of fault code, which was detailed explained in the manual book.

Company information:

![]()

![]()