-

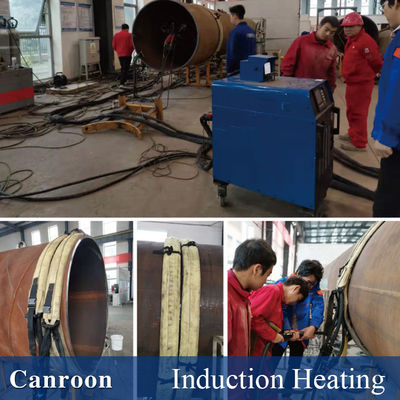

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Safety Protection | High | Product Model | CR2000-040B-14TF |

|---|---|---|---|

| Output Power | 36kW(duty Cycle 100%) | Voltage | 380V |

| Inductors | Can Be Customized | Power | 10-60KW |

| Inductance Range | 2.2-300uH | Input Current | 50-61A |

| Applications | Metal Heat Treatment And Welding Preheat | ||

| Highlight | 36kW Induction Heating Machine,Rapid Heating Induction Forging Machine,Induction Forging Machine 36kW |

||

CR2000-040B-14TF Induction Heating Machine With 2.2-300uH Inductance Range

Product Description:

This induction heating machine is a revolutionary device for metal heat treatment, designed to provide a safe, clean and rapid heating solution for shrink fit applications. It provides an intelligent and efficient way to heat metals quickly and accurately. It is equipped with a 3-phase voltage of 380-460V, an input current of 50-61A, a power range of 10-60KW and an inductance range of 2.2-300uH, making it capable of heating virtually any metal quickly and accurately. It is designed to be safe, clean and energy-efficient, providing users with a reliable, consistent and rapid heating solution. With this induction heating machine, users can easily and accurately heat metals, reducing the time and cost associated with shrink fit applications. It is a powerful and versatile heating solution that is capable of providing rapid, clean, and safe heating of metals.

![]()

Features:

- Product Name: Induction Heating Machine

- Input Current: 50-61A

- Applications: Metal Heat Treatment and Welding Preheat

- Weight: 95KG

- Product Model: CR2000-040B-14TF

- Inductors: Can Be Customized

- Advantages: Intelligent, Safe, Clean and Rapid Heating

Technical Parameters:

| Features | Parameters |

|---|---|

| Certifications | CE ISO Etc. |

| Input Frequency | 50-60Hz |

| Heating Speed | Fast |

| Applications | Metal Heat Treatment |

| Safety Protection | High |

| Power | 10-60KW |

| Output Power | 36kW(duty Cycle 100%) |

| Product Model | CR2000-040B-14TF |

| Output Frequency | 3-35KHz |

| Durability | Long-lasting |

| Energy saving | Yes |

| Joint anti-corrosion coating | Yes |

| PWHT | Yes |

Applications:

The Canroon CR2000 Induction Heating Machine is a reliable and precise device designed to provide effective and efficient heat treatments for a wide range of metals. It is certified with CE and ISO9001 and comes with a minimum order quantity of 1. The price for this machine is negotiable and it is packaged in a wooden box for delivery within 5-7 days. Payment terms include L/C, T/T, Western Union, and Paypal. Its supply ability is 300 Pieces/Pieces per Week. The input current range is 50-61A, inductance range 2.2-300uH, and the input frequency is 50-60Hz. Its fast heating speed makes it ideal for metal heat treatment, joint anti-corrosion coating, and welding preheat.

![]()

Customization:

Canroon CR2000 Induction Heating Machine is a high quality product with an outstanding performance, certified by CE and ISO9001. It is an intelligent, safe, clean and rapid heating machine, widely used for shrink fit, PWHT and other applications. It has a minimum order quantity of 1, and the price is negotiable. The weight of this machine is 95KG, with an output frequency of 3-35KHz and a power of 10-60KW. The delivery time is 5-7 days, with payment terms of L/C, T/T, Western Union, Paypal. It is delivered in a wooden box with reliable safety protection. We guarantee a supply ability of 300 pieces per week.

Support and Services:

We provide technical support and service for our Induction Heating Machine. Our qualified personnel are available to provide assistance with installation, maintenance, and troubleshooting issues.

We offer a wide range of technical assistance services that include but are not limited to:

- Installation and Setup Assistance

- Maintenance Services

- Troubleshooting and Repair

- Software Upgrades

If you have any questions or require assistance, please contact us at support@example.com.

![]()

FAQ: