-

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Input Power | 10KW~300KW | Temperature | >1000 ℃ |

|---|---|---|---|

| Cooling | Water Cooling | Resonance | Series Resonance |

| Control Model | Digital Control | Inductor | Customized |

| Operating Mode | Manual Or Automatic | Application | Brazing, Hardening, Annealing, Shrink Fitting, Etc |

| Highlight | Quenching High Frequency Induction Heating Machine,High Frequency Induction Heating Machine Rapid Heating,CR2100 induction brazing machine for copper pipe |

||

Hardening / Brazing / Annealing / Quenching High Frequency Induction Heating Machine Rapid Heating

CR2100 series induction heating machine is designed and manufactured by Canroon, with extreme

fast heating speed for almost all metal materials including: iron, copper, zinc, tin, aluminum, silver,

stainless steel, titanium, nickel, etc.

Equipped with infrared pyrometer and our consistently advanced temperature control system,

CR2100 can realize automatic and high precision control for the heating process, which makes

it a perfect system for heat treatment, especially for local heating.

CR2100 Induction Generator:

1. regualr type

10KVA~800KVA

Need external chiller for water cooling.

![]()

2. all-in-one type

10KVA~60KVA

Built-in chiller (water tank, pump, compressor), no need for connection of external cooler.

![]()

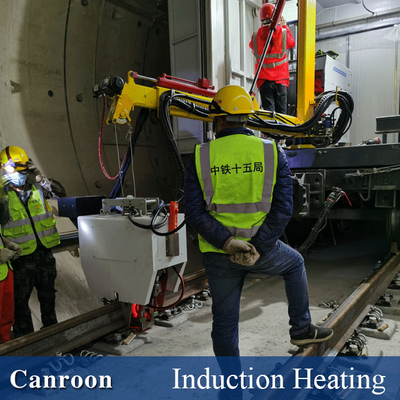

CR2100 HHT (hand-hold transformer):

Hand-held transformer are designed for your easy manual manipulation, and also can be integrated into

robot arm for automatic production.

Induction coils are easy for assemble and dismantle from hand-hold transformer, so you can connect with

different coil for different application.

![]()

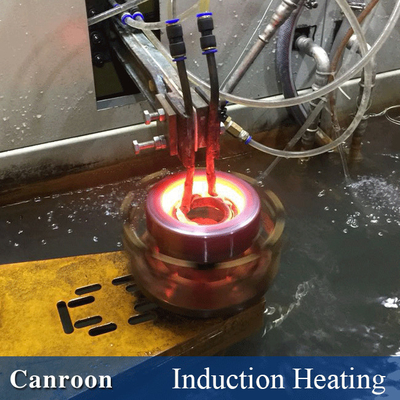

Detachable inductor:

Canroon will design and manufacturer different inductor according to client's specific case.

Inductor are manufactured in high processing technic, and customized with high quality, to ensure perfect

working with CR2100 induction heating generator.

![]()

Applications:

case hardening , Brazing , annealing, quenching , shrink fitting , painting / coating removal , straightening ,

curing , etc.

![]()

Materials:

All metal materials including iron , aluminum, zinc , tin , titanium, copper , nickel , silver , stainless steel , etc.

![]()

Competitive Advantages:

- High Temp. & Fast Heating

Able to reach >1000℃ within seconds.

- Easy Operation

CR2100 can be easily start&stop manually, and scan on workpieces surface to do local heating. It can also

be integrated into robot arm to serve automatic line.

- Accurate Control

The interface offers two basic control mode to choose including temperature control and power control.

The former one has 4 modes of Constant Temp., bake-out, HT (heat treatment), custom. The last one

has 2 modes of constant power and power VS time. Each mode offers different parameters to set. Thus

brings the benefit of wide applicability and precise control of heating process.

- Self Diagnosis

Once fault occurs, CR2000 will act with display of fault code, which was detailed explained in the manual book.

- Fault Record

Fault codes will display and be recorded for reference, and system will respond with protection action like

shutdown once fault occurs such as open-loop output or short out.

- Easy Maintenenace

Due to modular design, the maintance will be easy and low-cost.

- Customized Inductor

Canroon provided high-standard customized inductor to CR2100 induction generator, to help you

deal with workpieces of different shap&size.

Company line :

![]()