-

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Place of Origin | Shenzhen, China |

|---|---|

| Brand Name | Canroon |

| Certification | CE; ISO9001:2008 |

| Model Number | CR2000 |

| Minimum Order Quantity | 1 set |

| Price | FOB |

| Packaging Details | wooden case |

| Delivery Time | within 5 days if available in stock |

| Payment Terms | T/T, L/C, Western Union, MoneyGram |

| Supply Ability | 500 sets per month |

| Machine Name | Induction Heating Machine | Heating Method | Inductive Heating By Eddy Current |

|---|---|---|---|

| Application | Welding Preheat, PWHT | Induction Heating | IGBT |

| Power Source | Electric | Advantages | Small, Easy Operation |

| Weight (KG) | 20 | Temperature | 788℃ |

| Highlight | IGBT Induction Heating Machine,PWHT Induction Heating Machine,Induction Heating Machine 230V |

||

Energy Saving Induction Heating Machine For Shrink Fit

Our induction heater is used for pipe heat treatment like welding preheating, PWHT, applied in offshore

platform, oil and gas pipeline construction and repair, power plant, etc

Induction heating is the process of heating electrically conductive materials like metals by electromagnetic

induction, through heat transfer passing through an induction coil that creates an electromagnetic field

within the coil to melt down steel, copper, brass, graphite, gold, silver, aluminum, and carbide.

Thanks to its advantages, this equipment is widely used for PWHT(post welding heat treatment),

welding preheat, joint anti-corrosion coating in many different fields mainly in oil and gas pipeline construction.

Brief introduction of Energy Saving Induction Heating Machine For Shrink Fit :

Brand:Canroon

Power:20kVA

Duty cycle:100%

Heating method:inductive heating by eddy current

Application: welding preheat for steel pipes

Inductor type: split core inductor

Introduction of Energy Saving Induction Heating Machine For Shrink Fit :

Since our induction heater can be matched with the split core inductor, it is much easier and more suitable

for round tubes heat treatment, you just need to put the inductor around the pipes, then start the machine to

heat, it can reach the target temperature with shorter time, and the heating is equal and uniform.

Advantages of Energy Saving Induction Heating Machine For Shrink Fit :

1, Small and portable, suitable for hard-to-reach workpiece

2, Fast and uniform heating

3, Easy operation with split core inductor

![]()

Specifications:

| Model Number | CR2000-020B |

| Thermal conversion efficiency | More than 90% |

| Maximum Rated output40 | 20KW |

| Cooling Mode | Air cooled |

| Voltage | 3-phase 380-460V |

| Rated Output | 35KW at 100% duty cycle,1-35KHZ |

| TC input | 6 Circuit |

| Frequency | 3-15KHz |

| Control Model | Digital Control |

| Resonance | Series Resonance |

| Temperature | Max 1450°F |

| Transportation | By sea or By Air |

| Weight | 20KG |

| Certification | CE ISO9001:2008 |

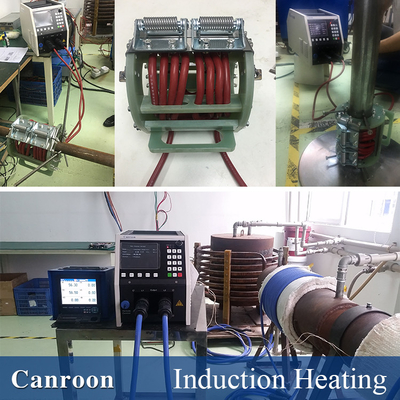

Picture of Energy Saving Induction Heating Machine For Shrink Fit :

Induction heating is used extensively in the metalworking industry to heat metals for hardening,

soldering, brazing, and tempering and annealing.

![]()

Induction heating is used extensively in the metalworking industry to heat metals for hardening, soldering,

brazing, and tempering and annealing. The induction-heating process is also employed in the fusion of

metals and the production of high-quality alloys.

Application details of Energy Saving Induction Heating Machine For Shrink Fit :

we can provide different inductors and soft induction cable for better application and performance, following

are some of the projects we ever did.

![]()

Induction heating is often used in the heat treatment of metal items. The most common applications are

induction hardening of steel parts, induction soldering/brazing as a means of joining metal components

and induction annealing to selectively soften an area of a steel part.

![]()

Technical parameters of Energy Saving Induction Heating Machine For Shrink Fit:

| Model | Temperature | Input Power | Input | Output | Dimension | Weight |

| CR2000-005B-12SF | 788℃ | 5kVA |

1-phase 220-240V 50-60Hz 20.8-22.7A |

4.2kW 5-60 KHz duty cycle 100% |

W:262.4mm H:304mm D:545mm |

18.6kg

|

|

CR2000-005B-14TF

|

788℃ | 5kVA |

3-phase 380-460V 50-60Hz 6.3-7.6A |

4.5kW 3-35 KHz duty cycle 100% |

W:262.4mm H:304mm D:545mm |

18.6kg

|

|

CR2000-010B-14TF

|

788℃ |

10kVA

|

3-phase 380-460V 50-60Hz 12.5-15A |

9kW 3-35 KHz duty cycle 100% |

W:262.4mm H:304mm D:545mm

|

18.6kg |

| CR2000-020B-14TF | 788℃ | 20kVA |

3-phase 380-460V 50-60Hz 24-36A |

18kW 3-35 KHz duty cycle 100% |

W:262.4mm H:304mm D:545mm |

18.6kg |

Accessories of Energy Saving Induction Heating Machine For Shrink Fit :

We offer multiple accessaries like thermocouple, thermocouple welding machine, digital temperature-recorder,

remote switchgear, output extension cable, insulation blanket, etc. Complete solution saves your time and

ensures you to start work soon after received our dellivery.

![]()

![]()

Company information:

![]()

![]()

FAQ:

1. Are you a trading company or manufacturer?

We are manufacturer located in Shenzhen, China, specialized in induction heating power for many years.

2. What's the delivery time for sample and bulk order?

Normally we have stock of the mini and medium items, 1-3 days for sample order, 15-40days for 20 GP and 40HQ quantity.

3. How is your products quality?

As a manufacturer, we have our own R&D team. And our machine has been well recognized around

our clients in China, as well as by those from abroad.

Packaging Details

Electic induction welding equipment is packed with plastic film, and fixed with rubber belt

Inside the case, covered with foamsOutside covered with customized wooden case.

Our Services

1. keep the quality first and make more products benefit to our customers' need

2.about our Online/Sale service

super and solid quality,Fast and punctual delivery,Standard export package or as customers’ need.

3.After-sale service

Assistance to your project,Repairing and maintenance if any problem occur in the warranty, Installation and

clerks training,Spare and wearing parts for free or with big discount,Any feedback of machines can be told to

us, and we will try our best to support you.