-

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Place of Origin | Shenzhen china |

|---|---|

| Brand Name | canroon |

| Certification | CE ISO9001:2008 |

| Model Number | CR2000 |

| Minimum Order Quantity | 1 piece |

| Price | negotiate a price |

| Packaging Details | Carton or depends on you |

| Delivery Time | A week after confirmed payment |

| Payment Terms | FOB |

| Supply Ability | 20 Piece/Pieces per Week |

| Machine Type | Induction Heating Machine | Core Components | PLC, Bearing, Gear |

|---|---|---|---|

| Key Selling Points | Multifunctional | Input Power | 380V 3-Phase |

| Temperature | Max 1450°F | Transportation | By Sea Or By Air |

| Resonance | Series Resonance | Control Model | Digital Control |

| Rated Output | 35Kw 1-35KHZ | Cooling Method | Water Cooling |

| Highlight | 380V Electric Induction Heater,Electric Induction Heater 35Kw,Uniform Heating Induction Hardening Machine |

||

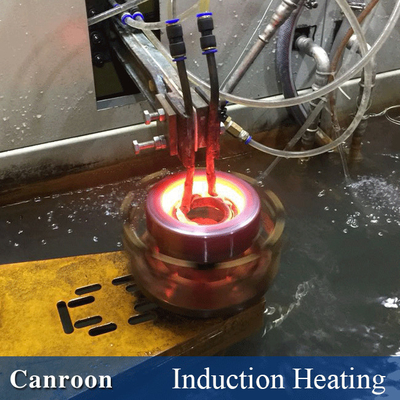

Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature

Induction heating is efficient, easily controlled, uses no energy when not heating, and puts the heat where

you want it, when you want it. No idle time, no massive refractories to heat, and close coupling enables you

to use energy in the best possible way.

Quick Detail Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature:

Type:Other

Place of Origin:China (Mainland)

Brand Name:Canroon

Model Number:CR2000-035A-14T

Voltage:380V

Current:53A

Rated Capacity:35KW

Rated Duty Cycle:35KW

Dimensions:880*663*982

Weight:201Kg

Usage:induction temperature stress relievers

Certification:CE ISO9001:2008

After-sales Service Provided:Overseas service center available

Process:Induction heating equipment

Input Power:380V,3-Phase

Temperature recorder:6 Channel temperature recorder

Description Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature:

The new induction preheater CR2000 can be used as an air-cooled system for temperatures up to 1450º F . The preheater features

multiple outputs, six control thermocouples to ensure uniform heating, significantly faster time to temperature than conventional heating,

and an extremely easy-to-use operator interface that allows the operator to program ramp and hold temperature times. It also tutors the

operator to achieve maximum output from the induction coils.

Applications Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature:

With the introduction of the Brazing and Gears Preheating , this simple and cost-effective heating process can be applied in the following

applications to deliver fast and consistent heat:

- Welding fabrication and construction;

- Preheating of welds;

- Post-weld heat treatment;

- Coating removal;

- Shrink Fit and so on

Specifications Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature:

|

Input Amperes at Rated Output |

380V:53A |

|

Thermal conversion efficiency |

More than 90% |

|

Maximum Rated output |

35KW |

|

Cooling Mode |

Air cooled |

|

Input Power |

380V 3-Phase,50HZ |

|

Rated Output |

35KW at 100% duty cycle,1-35KHZ |

|

TC input |

6 circuit |

|

Digital Recorder |

Optional |

|

Control Model |

Digital Control |

|

Resonance |

Series Resonance |

|

Temperature |

Max 1450°F |

|

Dimensions |

H:880MM W:663MM D:982MM |

|

Transportation |

By sea or By Air |

|

Weight |

201KG |

|

Warranty |

12 Months |

Brief introduction of Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature:

Induction heating is often used in the heat treatment of metal items. The most common applications are induction

hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction

annealing to selectively soften an area of a steel part.

Canroon is China leading manufacturer of induction heating machine, CR2100 series is our widely popular

both in China and oversea countries, digital control, modular design, LED display panel, HHT, detachable inductor,

soft induction cable, water cooling system.

![]()

Inductors are important part of induction heater, so it is precisely designed, manufactured by good quality material,

and tested many times before outgoing, it is detachable, and can be customized accoridng to your needs:

![]()

Applications of Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature:

Brazing, Annealing, Straightening, Hardening, Bolt Untighten, Shrink Fitting, Paint/Coating Removal, etc.

see the following detailed application of induction brazing for copper wire, heat exchanger, rotor coil, rotor bar,

short circuit ring, etc

![]()

Competitive Advantage Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature:

1.Versatile Mobility:optional running gear designed for construction and maintenance

2.On-board temperature control:provide for manual or temperature based programming in a simple-to-learn operator interface

3.Muitiple control thermocouple inputs:available to control on the hottest TC during heating and coolest TC during cooling for

4.uniform heating and quanlity

5.Open output detection:prevents system operation without a covered output receptacle(cable or protective plug)

6.Isolation fault protection:provides automatic system shut down power source output to ground.

7.Low consumable costs:No fuel costs and minimal insulation costs.insulation is resuable and may be used 50

time or more,reducing costs of disposal and replacement.

8.Uniform heating:maintained along and through the heat zone by using induction to heat within the material.the

surface of the part is nor marred by localized conducted heat at higher than specified temperatutes.

9.Time-to-temperature:faster than conventional processes due to methed of applying the heat,reducing the heating heating recyle time.

10.Improved working environment: With welding,welders are not exposed to open flame,explosive gases and hot

elements associated with fuel gas heating and resistance heating.

11.High energy-efficeent systems:(more than 90 percent efficient)transfers more energy to the part,decreassing heating times

and impoving power efficietnt.

12.Easy Set-up:achieved using preheat blankets or flexible heating cables combined with user-friendly insulation blankets.

Production line Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature::

![]()

Packaging Details Electric induction heater Uniform Heating Induction Hardening Machine 1450°F Max Temperature:

Plywood or wooden case, Adhesive wrap to prevent scratches,Plastic film to keep the machine together,

Foam plate and block to prevent shake,Other customer's requirements.

![]()

F&Q

1. Q: what is your MOQ?

A: We would like to do business with every clients. No matter how many sets they order, we would try our

best to meet his or her demands.

2. Q: Is your company a trading firm? or Factory?

A: We are a factory with 12 years experience in China. Welcome to our factory if you like

3. Q: How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

![]()

Tag:Brazing and Gears Preheating