-

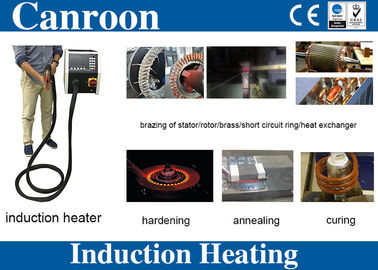

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Power | 10kw-50kw | Output Frequency | 10-40kHZ |

|---|---|---|---|

| Voltage | 3phase, 380-460V, 50/60HZ | Machine Size | Samll And Portable |

| Machine Weight | Light And Portable | Application | Metal Heat Treatment |

| Metal Heat Treatment | Brazing, Annealing, Hardening, Curing, Straightening,etc | Raw Materials | Nearly All Conductive Metals Like Copper, Steel, Iron, Brass, Aluminum, Etc |

| Suitable Industries | Widely Applied In Aviation, Metallurgy, Tools, Machinery, Automotive, Etc | Transformer | Coaxial Handheld Transformer |

| Inductor | Can Be Customized | ||

| Highlight | 10kw Induction Heating Equipment,40kHZ Induction Heating Equipment,10KVA Induction Brazing Equipment |

||

Power:10-50kw

Applications:metal brazing, annealing, hardening, straightening, curing, paint removal, etc

Frequency:10-40kHZ

Voltage: 3phase, 380-460V, 50/60HZ,

Application industries: aviation, metallurgy, tools and equipment, automotive, etc

Suitable metals: nearly all conductive metals like copper, steel, iron, brass, aluminum, etc

Induction heating equipment shows as follows:

![]()

With HHT and soft cable, easy to operate and handle, small size, and portable.

![]()

Applications of induction heating equipment:

Induction brazing of short circuit ring,

Induction brazing of copper wires on motor stator,

Induction brazing of rotor bar,

Induction brazing of rotor coil,

Induction brazing of heat exchanger,

etc

![]()

Induction Brazing of brass with Ag-Cu alloy as welding solder to make slip ring in motor for wide applications.

![]()

Induction annealing of steel plates, with good performance.

![]()

Induction Hardening of metals:

![]()

Induction Curing & paint removal:

![]()

HHT(hand held transformer) is easy to operate, and can be integrated with Robot Arm for automotion production, two buttons to control the machine working:

![]()

Inductors are important part of induction heater, it is precisely designed, manufactured

by good quality material, and tested many times before outgoing, it is detachable, and can be customized accoridng to your workpiece:

![]()

| model | Rated input voltage & frequency | Rated input power | Rated input current | Output frequency | Cooling water pressure / flow rate | Dimension |

| CR2100-010B-14TW1 | 3-phase /400V (±20%) 50/60Hz |

10KVA | 15A | 10~40KHZ |

4~6 bar ≥12L/min |

L: 581mm W: 283mm H: 334mm |

| CR2100-015B-14TW1 | 15KVA | 22A | ||||

| CR2100-020B-14TW1 | 20KVA | 30A | ||||

| CR2100-025B-14TW1 | 25KVA | 37A |

4~6 bar ≥19L/min |

|||

| CR2100-030B-14TW1 | 30KVA | 45A | ||||

| CR2100-035B-14TW1 | 35KVA | 53A | ||||

| CR2100-040B-14TW1 | 40KVA | 60A | ||||

| CR2100-050B-14TW1 | 50KVA | 75A |

Advantages:

· High Temp. & Fast Heating

Able to reach >1000℃ within seconds.

· Easy Operation

CR2100 can be easily start&stop manually, It can also be integrated into robot arm to serve automatic line.

· Accurate Control

The interface offers two basic control modes to choose including temperature control and power control. Thus brings the benefit of wide applicability and precise control of heating process.

· Fault Record

Fault codes will display and be recorded for reference.

· Easy Maintenance

Due to modular design, the maintenance will be easy and low-cost.

· Self-Diagnosis

Once fault occurs, CR2100 will act with display of fault code, which was detailed explained in the manual book.

· Customized Inductor

Canroon provided high-standard customized inductor to CR2100 induction generator, to help you deal with workpieces of different shap&size.

Manufacturing site:

![]()