-

Induction Heating Machine

-

High Frequency Induction Heating Machine

-

Portable Induction Heating Machine

-

PWHT Machine

-

Post Weld Heat Treatment Equipment

-

Induction Annealing Machine

-

Medium Frequency Induction Heating

-

Induction Heat Treatment Machine

-

Induction Hardening Machine

-

Induction Brazing Machine

-

Induction Tempering

-

Induction Stress Relieving

-

Induction Heating Equipment

-

Thermocouple Spot Welder

| Place of Origin | Shenzhen, China |

|---|---|

| Brand Name | Canroon |

| Certification | CE; ISO9001:2008 |

| Model Number | CR2000 |

| Minimum Order Quantity | 1 set |

| Price | FOB |

| Packaging Details | wooden case |

| Delivery Time | within 5 days if available in stock |

| Payment Terms | T/T, L/C, Western Union, MoneyGram |

| Supply Ability | 500 sets per month |

| Machine Name | Induction Heating Machine | Power | 5kw, 10kw |

|---|---|---|---|

| Application | Pipe Joint Anti-corrossion Coating, Welding Heat Treatment | Industry | Pipeline, Offshore, Power Plant |

| Frequency | High Frequency | Induction Heating | IGBT |

| Highlight | induction heat treating equipment,induction heating equipment |

||

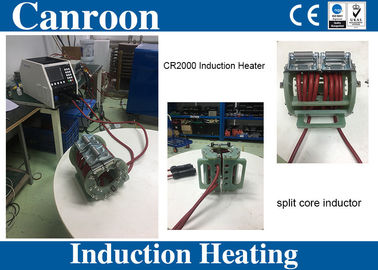

Portable Induction Heating Machine for Pipe Joint Anti-corrosion Coating

Detailed picture of portable induction heating machine for pipe joint anti-corrossion coating:

Small and portable, 5kw, 10kw, digital control, modular design, connect with split core inductor, this type inductor can best suit your pipe, and equally heating, easily to open and close.

![]()

Technical parameters of portable induction heating machine for pipe joint anti-corrossion coating:

| Model | Temperature | Input Power | Input | Output | Dimension | Weight |

| CR2000-005B-12SF2 | 788℃ | 5kVA |

1-phase 220-240V 50-60Hz 20.8-22.7A |

4.2kW 5-60 KHz duty cycle 100% |

W:242.9mm H:295.2mm D: 504.4mm

|

16kg

|

|

CR2000-005B-14TF1

|

788℃ | 5kVA |

3-phase 380-460V 50-60Hz 6.3-7.6A |

4.5kW 3-35 KHz duty cycle 100% |

W:263mm H:302mm D:535mm

|

18.6kg

|

|

CR2000-010B-14TF1

|

788℃ |

10kVA

|

3-phase 380-460V 50-60Hz 12.5-15A

|

9kW 3-35 KHz duty cycle 100% |

W:263mm H:302mm D:535mm

|

18.6kg |

Application details of portable induction heating machine for pipe joint anti-corrossion coating:

Our portable induction heating machinecan be applied in joint anti-corrosion coating in oil and gas pipeline construction, offshore platform, power plant, work very well, and high efficiency.

![]()

Accessories of portable induction heating machine for pipe joint anti-corrossion coating:

We offer multiple accessaries like thermocouple, thermocouple welding machine, digital temperature-recorder, remote switchgear, output extension cable, insulation blanket, etc. Complete solution saves your time and ensures you to start work soon after received our dellivery.

![]()

Advantages of digital control induction heating machine 5kw for welding preheating PWHT:

- precise control

We have display panel to show working parameters, and temperature recorder can feedback PWHT curve, you can print it.

- Various Control Mode

The interface offers two basic control mode to choose including temperature control and power control. Thus brings the benefit of wide applicability and precise control.

- Fault Record

Fault codes will display and be recorded for reference, and system will respond with protection action like shutdown once fault occurs such as open-loop output or short out.

- Easy Maintenenace

Due to modular design, the maintance will be easy and low-cost.

- Self Diagnosis

Once fault occurs, induction heater will display fault code, which was detailed explained in manual book.

- High Efficiency

This uniquely energy-efficient process converts up to 90% of the expended energy into useful heat, and time-to-temperature is faster than conventional processes, reducing cycle time.

- Uniform Heating

The heat is induced within the part itself by alternating electrical current, thus uniform temperature throughout the heating zone is realized.

Company information:

![]()